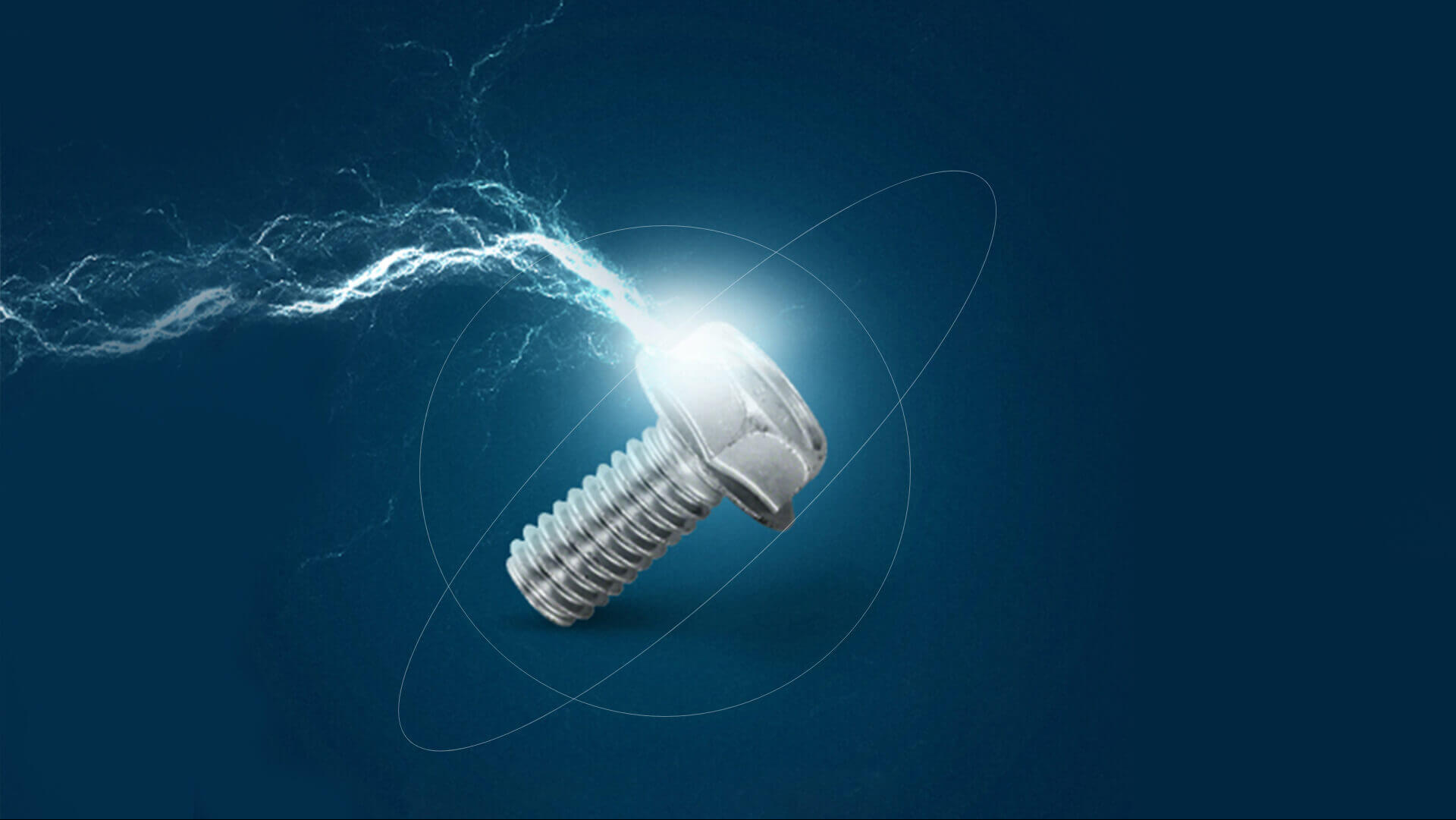

YENİLENEBİLİR ENERJİ

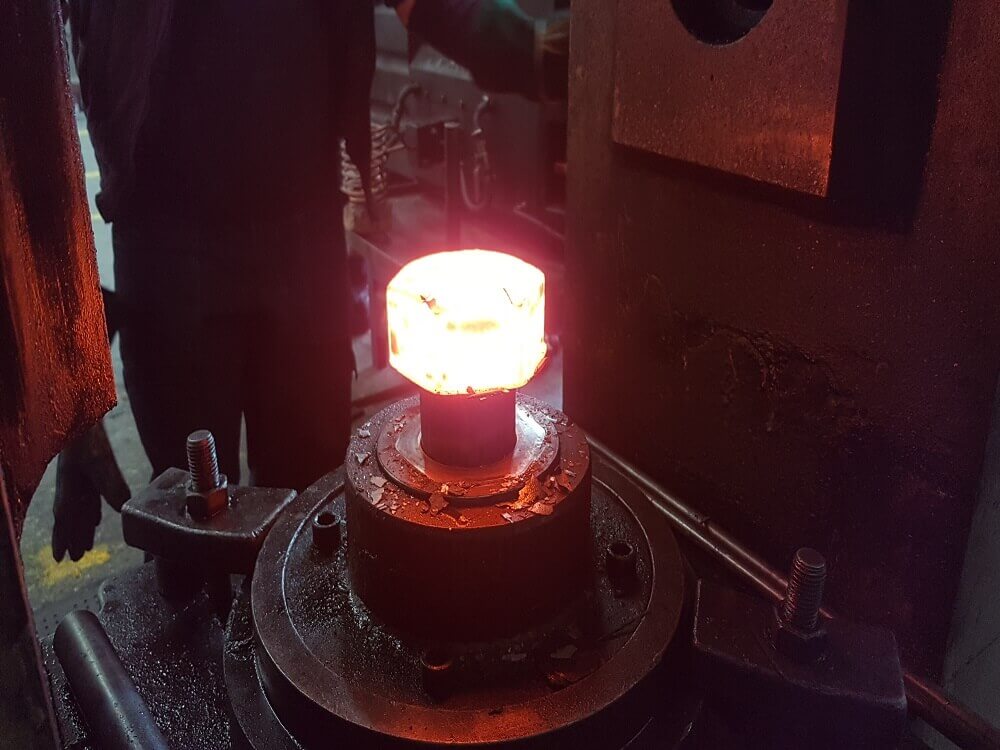

Üretimde maksimum kalite prensibi...

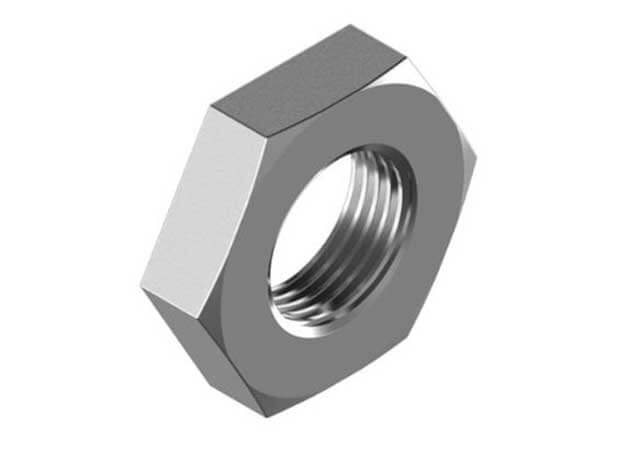

OTOMOTİV

Bir otobüste ortalama 3500 adet cıvata bulunur.

MAKİNE

2019’da makine sektöründe kullanılmak üzere ortalama 627.696 adet cıvata satıldı.

YILLIK ÜRETİM

1.250.000 ADET

"consider it done..."